Plain product

-

With a good reputation reducing hexagon Nipples for construction malleable iron pipe fitting

1. Adequate-net weight, no cutting comers.

2. Except for standard weight, other optional weight series are available. Heavy and light.

3.We guarantee 100% pressure testing.

4. We offer a wide range of products in three different series :high, medium and low .we are sure we can meet your requirements. Our high-quality range caters to those looking for top-notch performance and durability, while our mid-range range strikes a balance between functionality and affordability. Finally, our low range offers an affordable option without compromising quality. Whatever your needs and preferences, we are confident that we can provide a product that exactly meets your requirements.

-

Hot selling galvanized and black malleable iron pipe fittings reducing hexagon nipples for fire fighting system

1. Adequate-net weight, no cutting comers.

2. Except for standard weight, other optional weight series are available. Heavy and light.

3.We guarantee 100% pressure testing.

4. We offer a wide range of products in three different series :high, medium and low .we are sure we can meet your requirements. Our high-quality range caters to those looking for top-notch performance and durability, while our mid-range range strikes a balance between functionality and affordability. Finally, our low range offers an affordable option without compromising quality. Whatever your needs and preferences, we are confident that we can provide a product that exactly meets your requirements.

-

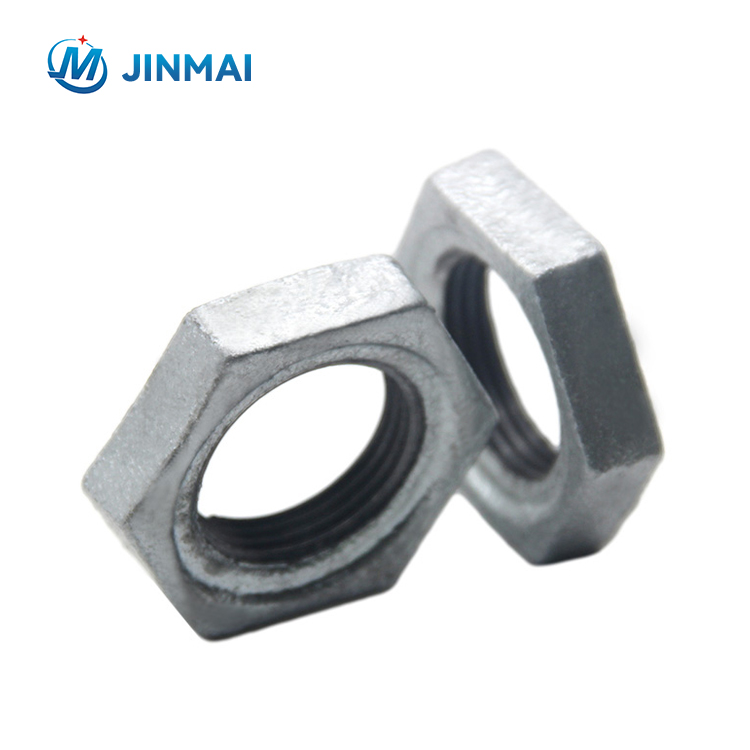

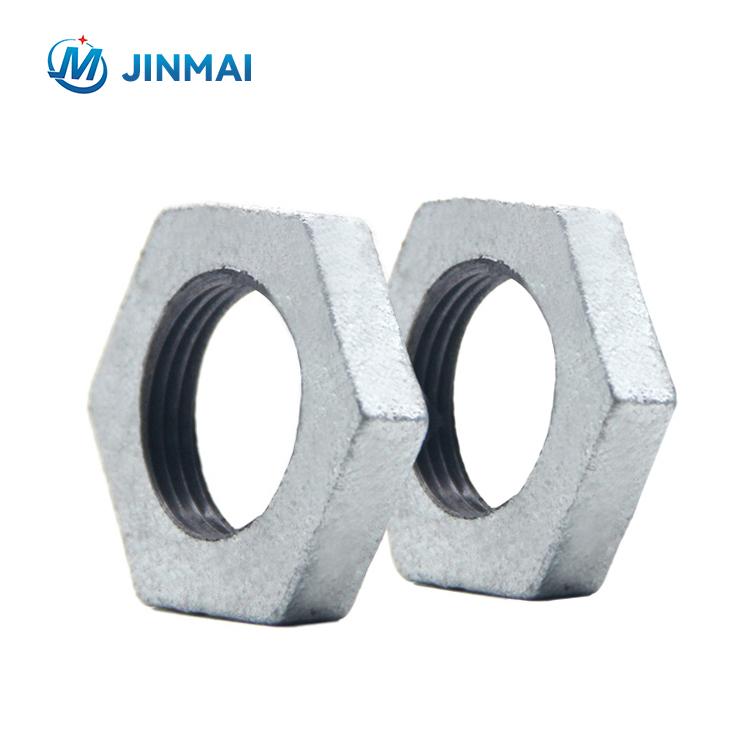

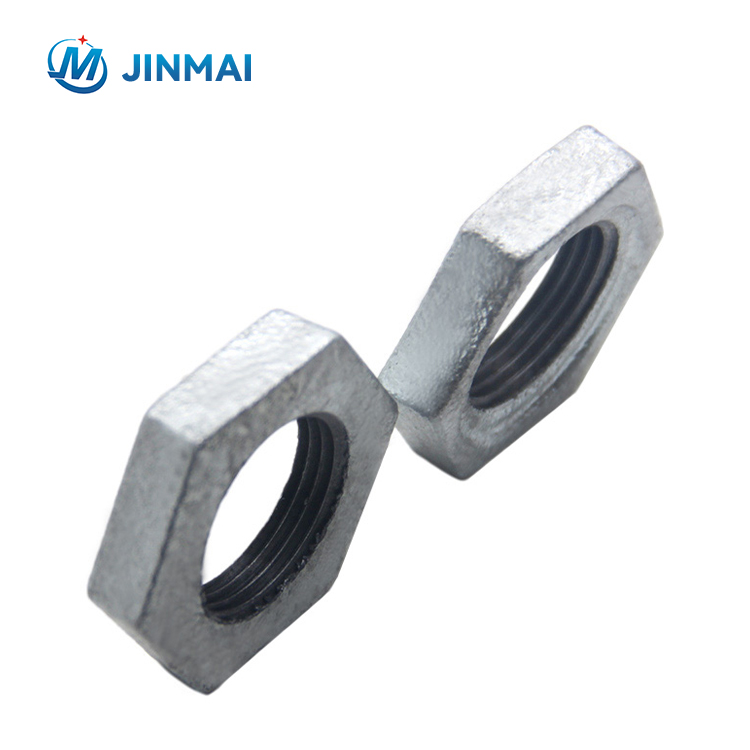

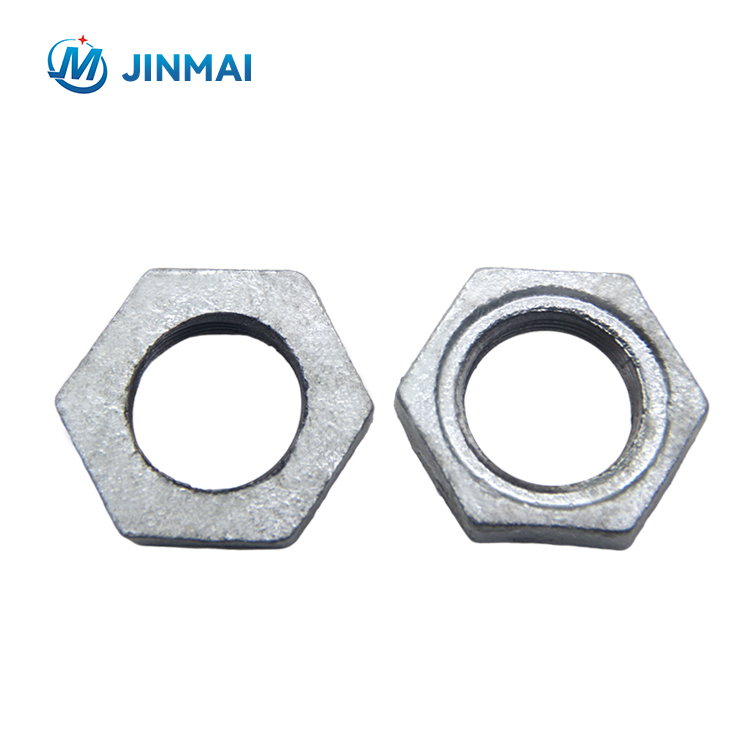

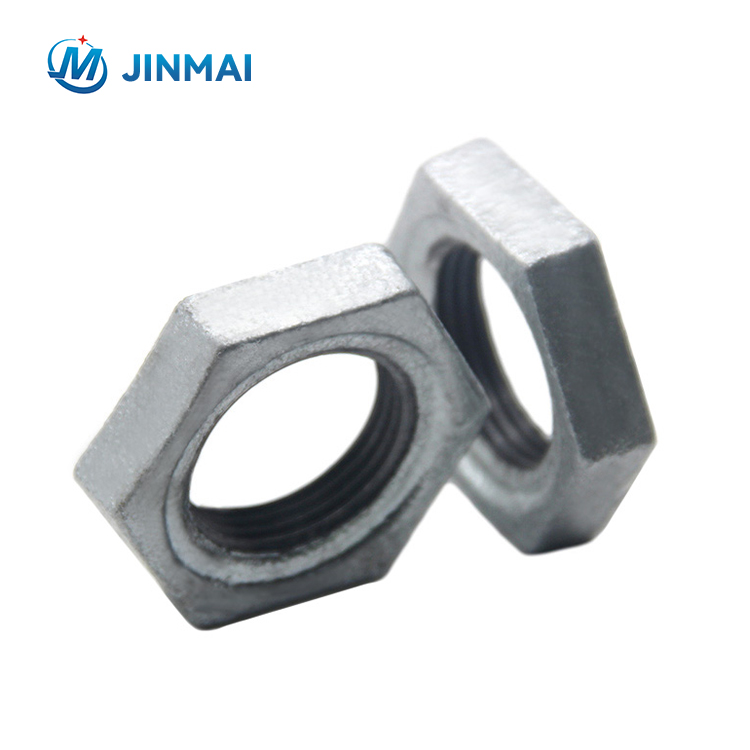

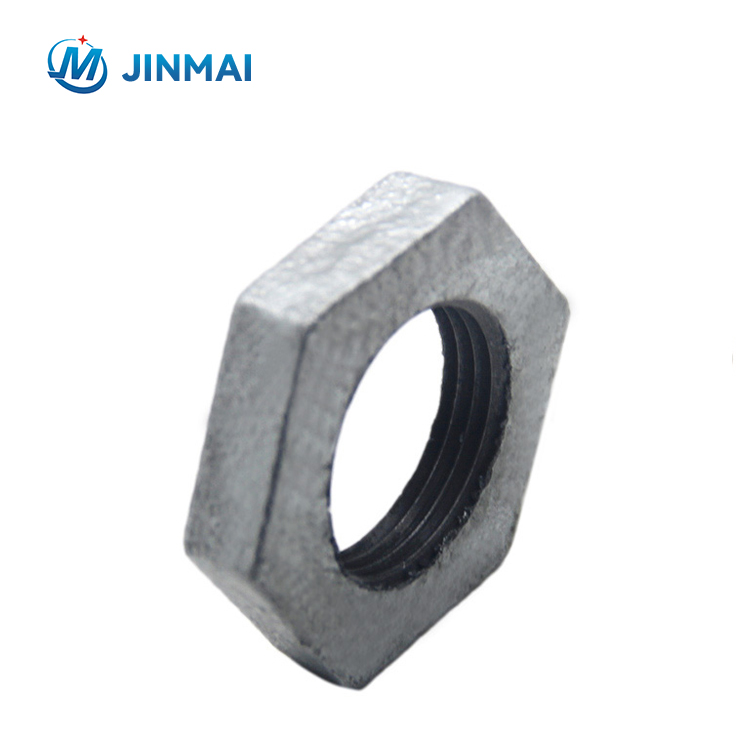

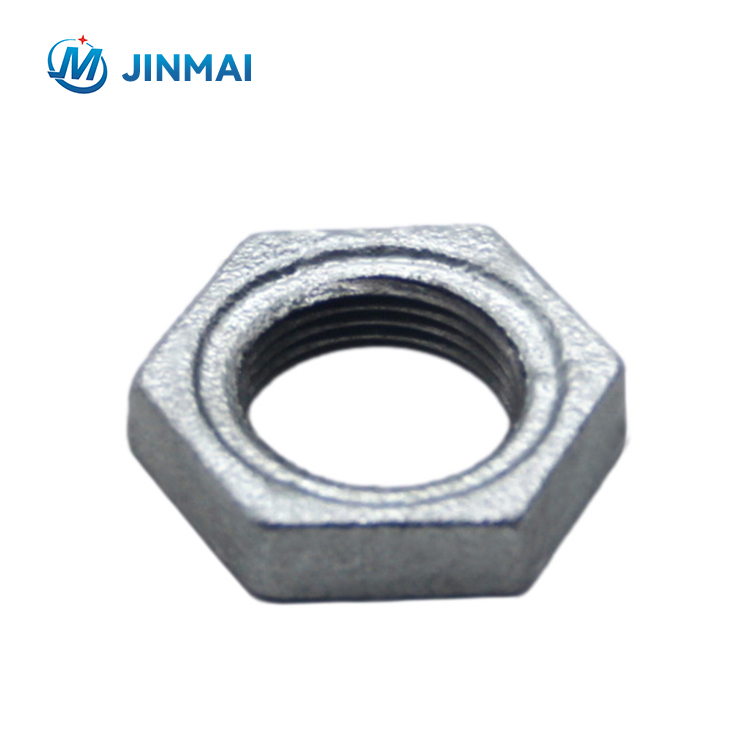

3/8 malleable iron pipe fitting coupling pipe thread locknut for electric power construction

Lock nuts are commonly used in machinery and various industries because of their ability to self-lock using friction between the nut and the bolt. However, the self-locking reliability of the lock nut will be reduced under dynamic load. In order to ensure the reliability of nut locking in critical situations, additional anti-loosening measures are taken. These measures can include the use of additional locking mechanisms such as spring washers, cotter pins, or adhesive thread locking compounds. These anti-loosening measures increase the vibration resistance and prevent the nut from loosening accidentally. By adopting these measures, the integrity of the lock nut can be maintained, ensuring the stability and safety of the machinery or equipment in various applications.

-

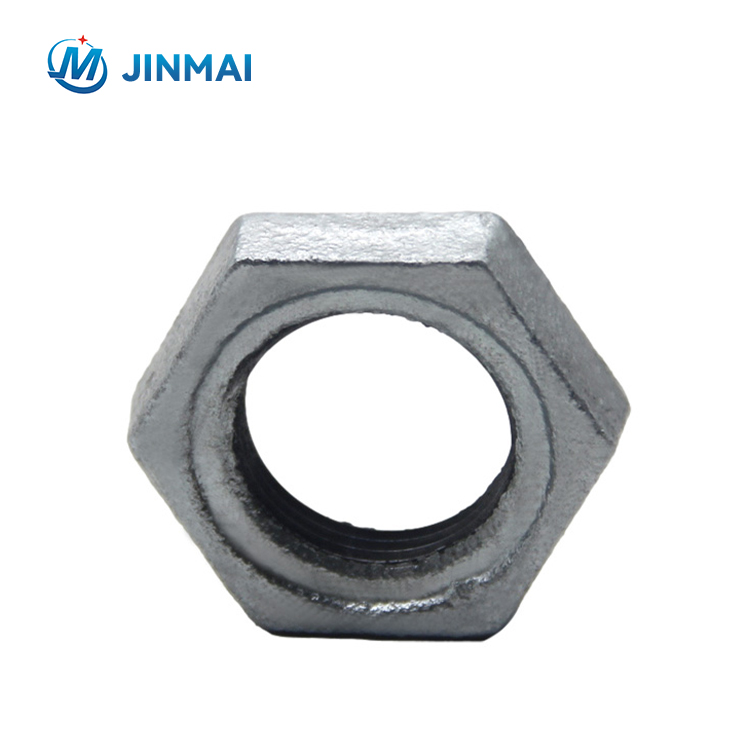

Wholesale manufacturer direct supply malleable iron pipe fitting locknut with quality assurance

Lock nuts are commonly used in machinery and various industries because of their ability to self-lock using friction between the nut and the bolt. However, the self-locking reliability of the lock nut will be reduced under dynamic load. In order to ensure the reliability of nut locking in critical situations, additional anti-loosening measures are taken. These measures can include the use of additional locking mechanisms such as spring washers, cotter pins, or adhesive thread locking compounds. These anti-loosening measures increase the vibration resistance and prevent the nut from loosening accidentally. By adopting these measures, the integrity of the lock nut can be maintained, ensuring the stability and safety of the machinery or equipment in various applications.

-

Wholesale Manufacturer Direct Supply Hardware Malleable Backnuts Pipe Fitting for oil transportation

Lock nuts are commonly used in machinery and various industries because of their ability to self-lock using friction between the nut and the bolt. However, the self-locking reliability of the lock nut will be reduced under dynamic load. In order to ensure the reliability of nut locking in critical situations, additional anti-loosening measures are taken. These measures can include the use of additional locking mechanisms such as spring washers, cotter pins, or adhesive thread locking compounds. These anti-loosening measures increase the vibration resistance and prevent the nut from loosening accidentally. By adopting these measures, the integrity of the lock nut can be maintained, ensuring the stability and safety of the machinery or equipment in various applications.

-

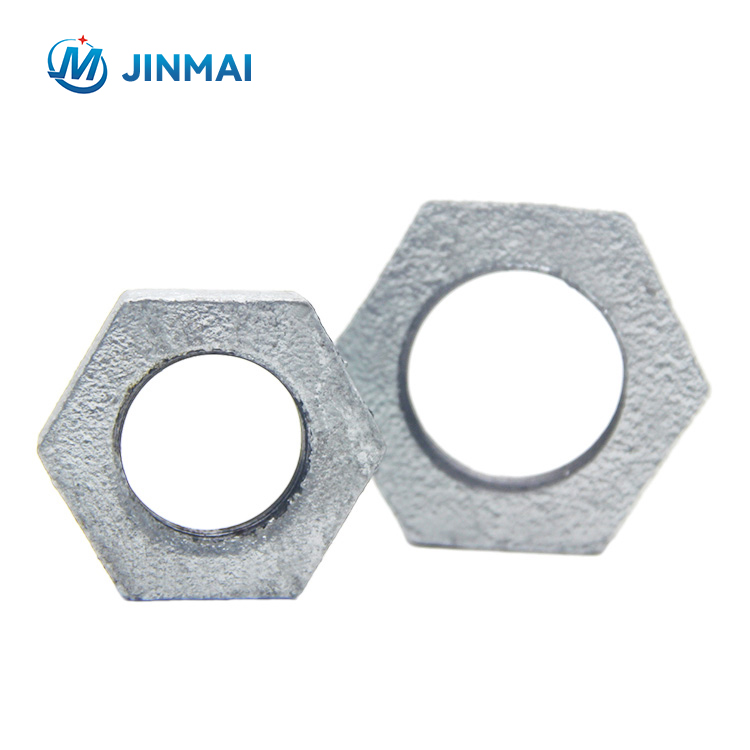

Best Quality Malleable Iron Pipe Fittings Fingerboard Locknuts Used for diy industrial shelves

Lock nuts are commonly used in machinery and various industries because of their ability to self-lock using friction between the nut and the bolt. However, the self-locking reliability of the lock nut will be reduced under dynamic load. In order to ensure the reliability of nut locking in critical situations, additional anti-loosening measures are taken. These measures can include the use of additional locking mechanisms such as spring washers, cotter pins, or adhesive thread locking compounds. These anti-loosening measures increase the vibration resistance and prevent the nut from loosening accidentally. By adopting these measures, the integrity of the lock nut can be maintained, ensuring the stability and safety of the machinery or equipment in various applications.

-

China Supplier High Quality Hardware Malleable locknut Pipe Fitting for oil transportation

Lock nuts are commonly used in machinery and various industries because of their ability to self-lock using friction between the nut and the bolt. However, the self-locking reliability of the lock nut will be reduced under dynamic load. In order to ensure the reliability of nut locking in critical situations, additional anti-loosening measures are taken. These measures can include the use of additional locking mechanisms such as spring washers, cotter pins, or adhesive thread locking compounds. These anti-loosening measures increase the vibration resistance and prevent the nut from loosening accidentally. By adopting these measures, the integrity of the lock nut can be maintained, ensuring the stability and safety of the machinery or equipment in various applications.

-

Factory custom hex round nut lock tee nut hexagon metal locknut GI Pipe Fitting Parts

Lock nuts are commonly used in machinery and various industries because of their ability to self-lock using friction between the nut and the bolt. However, the self-locking reliability of the lock nut will be reduced under dynamic load. In order to ensure the reliability of nut locking in critical situations, additional anti-loosening measures are taken. These measures can include the use of additional locking mechanisms such as spring washers, cotter pins, or adhesive thread locking compounds. These anti-loosening measures increase the vibration resistance and prevent the nut from loosening accidentally. By adopting these measures, the integrity of the lock nut can be maintained, ensuring the stability and safety of the machinery or equipment in various applications.

-

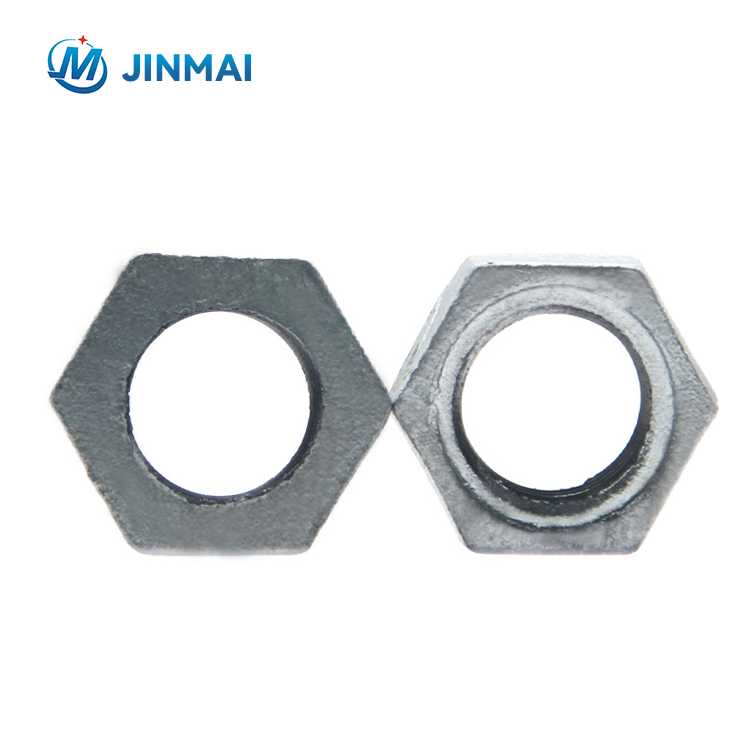

Plumbing Black Nut Malleable Iron Pipe Fittings Backnuts or Locknuts in Female BS\NPT Threads of 1\4 to 6 Inch

The self-locking principle of the nut relies on the friction force generated between the nut and the bolt. However, this self-locking capability may become less reliable under dynamic loads. In order to ensure that the nut can be firmly locked in an emergency, anti-loosening measures must be taken. Lock nuts are an effective solution for preventing nuts from loosening. The anti-loosening effect of the lock nut mainly depends on the interaction force between the nut and the bolt thread. Various methods can be employed to enhance this interaction force. Structural modifications to the nut threads, such as adding serrations or flanges, increase friction. Another method is to roughen the surface of the nylon lock nut to produce a higher coefficient of friction. Additionally, surface treatments on the threads, such as coatings or platings, can enhance the interaction between the nut and bolt threads and increase resistance to loosening. By implementing these measures, the reliability and stability of nut locking are guaranteed even under dynamic loads.

-

Electrical Galvanized Backnuts gi Malleable Iron Pipe Fittings of BS/NPT Threads gi Locknuts with 1/2 Inch Used for Oil

The self-locking principle of the nut relies on the friction force generated between the nut and the bolt. However, this self-locking capability may become less reliable under dynamic loads. In order to ensure that the nut can be firmly locked in an emergency, anti-loosening measures must be taken. Lock nuts are an effective solution for preventing nuts from loosening. The anti-loosening effect of the lock nut mainly depends on the interaction force between the nut and the bolt thread. Various methods can be employed to enhance this interaction force. Structural modifications to the nut threads, such as adding serrations or flanges, increase friction. Another method is to roughen the surface of the nylon lock nut to produce a higher coefficient of friction. Additionally, surface treatments on the threads, such as coatings or platings, can enhance the interaction between the nut and bolt threads and increase resistance to loosening. By implementing these measures, the reliability and stability of nut locking are guaranteed even under dynamic loads.

-

Female Threaded Backnuts gi Malleable Iron Pipe Fittings with BS/NPT Threads in a Size of 1/2 Inch

The self-locking principle of the nut relies on the friction force generated between the nut and the bolt. However, this self-locking capability may become less reliable under dynamic loads. In order to ensure that the nut can be firmly locked in an emergency, anti-loosening measures must be taken. Lock nuts are an effective solution for preventing nuts from loosening. The anti-loosening effect of the lock nut mainly depends on the interaction force between the nut and the bolt thread. Various methods can be employed to enhance this interaction force. Structural modifications to the nut threads, such as adding serrations or flanges, increase friction. Another method is to roughen the surface of the nylon lock nut to produce a higher coefficient of friction. Additionally, surface treatments on the threads, such as coatings or platings, can enhance the interaction between the nut and bolt threads and increase resistance to loosening. By implementing these measures, the reliability and stability of nut locking are guaranteed even under dynamic loads.

-

GI Steel Lock Nut Cable Accessories Cable Gland Nut M Thread Locknut and Bushing

The self-locking principle of the nut relies on the friction force generated between the nut and the bolt. However, this self-locking capability may become less reliable under dynamic loads. In order to ensure that the nut can be firmly locked in an emergency, anti-loosening measures must be taken. Lock nuts are an effective solution for preventing nuts from loosening. The anti-loosening effect of the lock nut mainly depends on the interaction force between the nut and the bolt thread. Various methods can be employed to enhance this interaction force. Structural modifications to the nut threads, such as adding serrations or flanges, increase friction. Another method is to roughen the surface of the nylon lock nut to produce a higher coefficient of friction. Additionally, surface treatments on the threads, such as coatings or platings, can enhance the interaction between the nut and bolt threads and increase resistance to loosening. By implementing these measures, the reliability and stability of nut locking are guaranteed even under dynamic loads.